- myLubrizol

-

-

Search Engineered Polymers

The ingredient in paint protection film (PPF) is thermoplastic polyurethane (TPU), and the manipulation of the TPU molecule allows us to alter PPF performance in many ways. Changes to TPU formulations can influence optical clarity, color, elasticity, UV resistance, and a variety of other PPF attributes. As the science behind PPF continues to evolve, and our ability to manipulate the TPU molecule expands, the question facing TPU suppliers and PPF brand owners is shifting from “what can we do” to “what should we do?” That answer is more complicated, but it has the potential to unlock the future of PPF innovation.

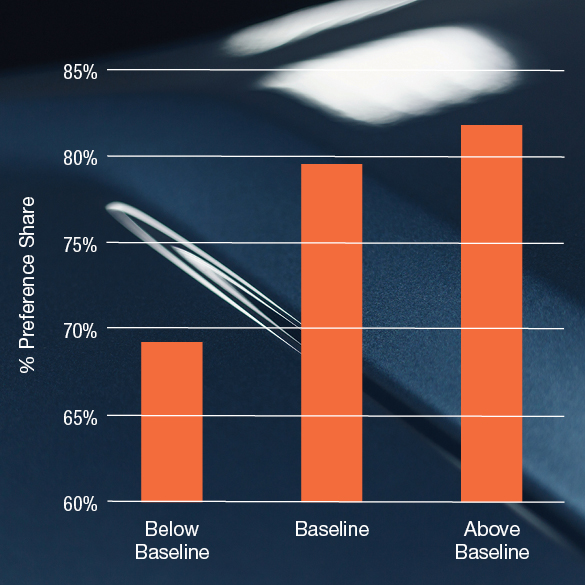

In 2020, we conducted a conjoint survey involving hundreds of installers in China. We used structured interview questioning to further understand how installers and their customers value different PPF attributes. We assessed the value and interrelationship of these attributes and concluded that when several of them were optimized individually, they contributed to an optimum product configuration in the eyes of installers. Improving only a few of these attributes increased the market preference for an ideal product over the baseline product used in our study, highlighting that the whole really is greater than the sum of its parts.

The study revealed some interesting details in how installers valued certain attributes and gave us greater context on how they define “important.” For example, warranty length was a significant driver of market preference – up to a point. Decreasing the length of the warranty below the established baseline reduced share of preference by 10% – a big swing. But improving the warranty hardly moved the needle – increasing preference by just 3%.

That data is valuable when it comes to PPF product development. When refining formulations and developing new PPF products, improving some attributes may have stronger return than others. In regard to warranty length, we saw that remaining consistent with the baseline warranty period was important. But continuing to refine a product to extend beyond this period had diminishing returns.

Protecting against paint chips may have been the reason PPF was first invented, but in 2020 it was taken for granted in the China market. Ranked in the bottom quartile of importance among the attributes studied, chip resistance is now considered table stakes. The drivers for product performance – at least in China in 2020 – were far more connected to aesthetic performance.

This research helps us answer that central question: “What should we do?” It isn’t a question a TPU supplier or PPF brand owner can answer on their own. We can make assumptions about what characteristics really matter to PPF installers and their customers, but PPF has grown into a billion-dollar global business. Assumptions aren’t good enough.

That’s why at Lubrizol, we go directly to the source. Our 2020 study is one example of the type of research we conduct. These are detailed, analytically-sound studies of the PPF market in key regions around the world.

The process produced a rich, detailed view of installers’ perspectives on PPF, how they prioritize various performance characteristics, and led to the ability to predict preference for various product configurations through performance tradeoff and ultimately an analytically-derived, optimized PPF product.

We can utilize the findings from this market study and others to guide the development of the next generation of PPF material, starting with the construction of the TPU molecule but not ending there. The research is a catalyst for innovation not just in materials, but across systems in the PPF ecosystem. It empowers us to engage meaningfully with film processors, coaters, PPF brand owners, and installers to coordinate and optimize our efforts and improve the products we’re making in multiple ways.

Through the 2020 China research we mapped PPF brand preference in addition to preference for specific PPF attributes. By looking at various brands and how they’re ranked in a variety of areas, including installation and lifecycle, we can identify clear brand preferences among installers. The anonymized chart here shows obvious differences between several prominent PPF brands, revealing opportunity to strengthen market perception.

Where the Research Meets the Road

Streamlining PPF Product Development Through Simulated Installation

Fostering PPF Innovation with a State-of-the-Art Pilot Film Extrusion Line

Achieving Process Excellence for High Quality PPF

Expanding PPF Possibilities Through Materials Science Innovation

Capitalizing on PPF Market Expansion

Untapping the Potential of PPF Performance Characteristics

Advantages of Predictive Weathering Tests