For many years, polytetrafluoroethylene (PTFE) has been a key component in printing inks to deliver a variety of beneficial properties to applications like cans, coils and graphic arts. Unfortunately, making low molecular weight PTFE, the type used for inks, requires an irradiation process that has been demonstrated to generate PFAS [e.g. perfluoro octanoic acid (PFOA) and perfluoro-octane sulfonic acid (PFOS)] as byproducts.

Traditional manufacturing processes are known to generate PFOA in the range of parts per million. Regulatory measures targeting specific types of per- and polyfluoroalkyl substances (PFAS) have been in place for years, with some measures restricting certain PFAS down to parts per billion (ppb) levels. One example that impacts PTFE is the recent European Union REACH Regulation (EC) No. 1907/2006, on Per-Fluoro-Octanoic-Acid (PFOA) and its salts as persistent organic pollutants (POPs).

Within this regulatory environment, ink formulators and manufacturers around the world must be prepared to adapt their ink technologies to be PFOA compliant. That means traditional PTFE will need to be replaced with low-PFOA containing PTFE or PTFE-free alternatives using new low-PFOA PVDF or PVDF-free resins. In addition to regulations, PTFE stability properties that have driven use in many applications and its halogen content also impact cradle-to-cradle policies.

PTFE-based wax additives are common fluoropolymers used in a wide range of industries for their many desirable properties, including exceptional chemical resistance, low coefficient of friction and enhanced surface durability. These properties make them especially useful in printing inks. While regulatory measures continue to evolve, it’s been well known for years that alternatives would need to be developed – and the industry has responded.

PTFE-Free Wax Additives

Lubrizol has developed PTFE-free wax additives using new and alternative raw materials that exhibit similar functional performance as PTFE-based options. Testing done on these PTFE-alternative wax additives have shown they deliver similar properties to PTFE-containing additives (see testing highlights below), which has led to their commercial development under the Lanco™ Surface Modifiers brand. They are available in micronized and dispersed forms of wax additives.

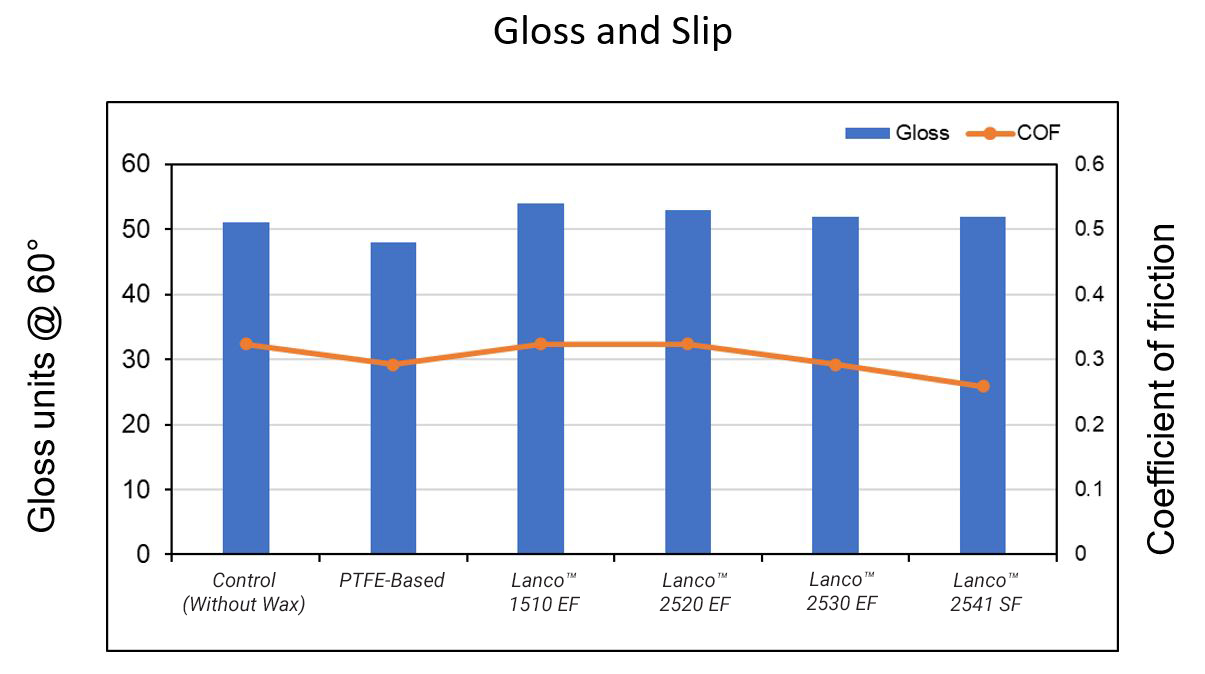

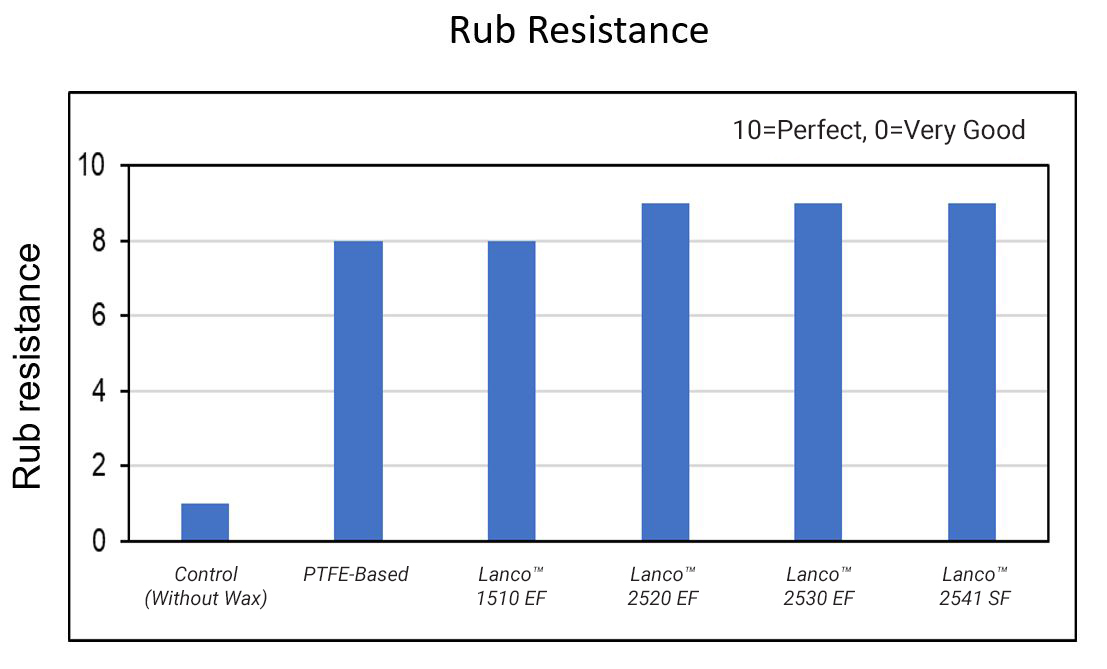

For example, PTFE-free wax additives offer a number of benefits, such as rub resistance and slip, when used as a replacement for waxes containing PTFE. Additionally, these additives are suitable for aqueous, solvent-based and 100% UV ink systems. When these waxes are incorporated into an ink formulation, it not only improves gloss retention, but also reduces coefficient of friction and increases the rub resistance.

Testing Results

Testing analyzed rub resistance, gloss and coefficient of friction of the ink with the Lanco™ PTFE-free waxes in water-based acrylate resin ink, solvent-based NC ink, and UV acrylate resin ink. The tests followed standard methods used by the industry for evaluating print properties of ink systems using 2% active content with application on Leneta paper 3NT-31 backside and a drying time of 24 hours.

Performance Data in UV Acrylate Resin Ink

Exceptional Surface Protection without PTFE

Specifically developed for the ink and packaging industries, Lubrizol offers a range of Lanco™ PTFE-free micronized waxes to significantly improve rub resistance while reducing coefficient of friction (COF) and maintaining gloss comparable to traditional PTFE-based wax additives. These PTFE-free wax additives are easy to handle and designed for use in water-based, solvent-based and UV inks. Lubrizol is also developing more products to meet specific customer needs and provide additives for a wider range of applications.

Additional benefits include:

- Highly effective surface modification

- Halogen-free functional PTFE replacement additives

- Suitable for use in water, solvent-based and UV inks

- Small and narrow particle size distribution

- EU 10/2011 and FDA 21 CFR 175.300 compliant

Contact us to learn more about our PTFE-alternative wax additives for printing inks.