Waxes with bio-based content for coatings and inks are not new, but there are many new types of bio-based materials being tested and developed for commercial use as wax additives. Some of these newer alternatives offer tremendous promise in delivering performance that rivals that of polyethylene waxes in enhancing and protecting appearance, feel, slip, abrasion and scratch resistance, and overall durability of the coating or ink formulation.

Carnauba-type waxes have historically been the primary option that could be considered bio-based and renewable. These purely plant-based waxes, which are derived from the leaves of the carnauba palm, have been commercially available and popular for many years. They provide high slip properties, scratch resistance and good film clarity. Fatty acid amides are another bio-based option derived from plant and animal sources, providing excellent anti-block and release properties, but limited scratch protection.

In recent years, more types of wax technologies with bio-based content have grown in popularity as they become more viable in addressing both performance needs and the growing demand for raw materials that deliver sustainability benefits and reduce the environmental impact of coatings and inks.

There are waxes derived from the leaves of the Candelilla shrub, sunflower seeds, soy, palm, sugar cane bagasse or extracted from the bran oil of rice. Natural waxes can also be derived from animals and insects (like beeswax). Two of the most promising options have been rice bran and sunflower seeds.

Rice bran oil for wax is extracted from the outer bran or husk of rice grains, which is not consumed for food - so it does not compete with the food supply. Rice bran wax has a melting point of 77-86 °C. Sunflower wax comes from grinding unpeeled sunflower seeds and has a melting point of 74-80 °C.

Testing and Developing Bio-Derived Alternatives

With extensive experience in micronized and liquid wax preparations for coatings and inks, Lubrizol is working on developing other natural, bio-based waxes with expectations of launching these products in the not-too-distant future. Because rice bran and sunflower-based waxes have demonstrated the most success, testing and development are focused on these two alternatives.

Following are testing results comparing how these two bio-based waxes perform – including four versions of rice bran materials – against a synthetic control and compared to a control coating with no wax at all in the areas of scratch, slip and matting.

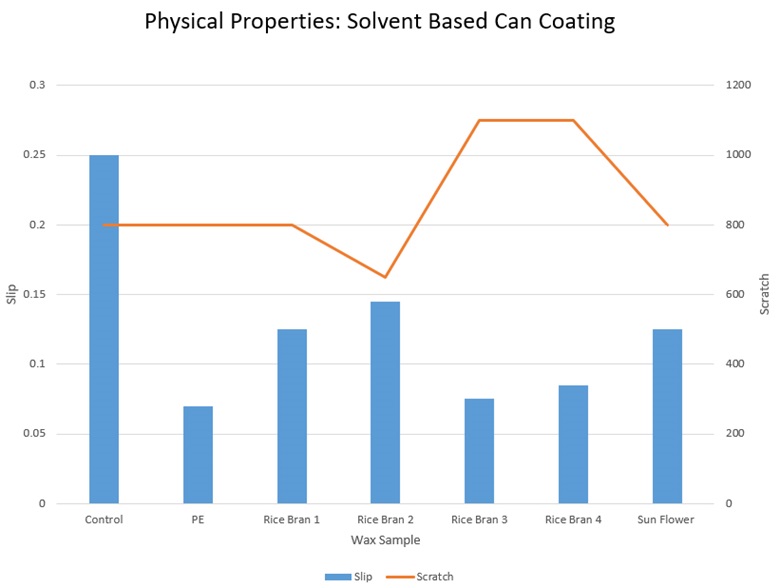

Can Coating Test Results

In can coatings, wax acts as a protective layer to protect the brand on the outside of the can to keep it from getting scratched or damaged by providing enhanced slip and scratch abrasion resistance. The chart below (Figure 1) shows testing of slip (coefficient of friction) in the bars and the line graph measures scratch (amount of weight it takes to make a scratch) in a solvent-based can coating. Rice bran 3 and 4 yield better scratch resistance than the other materials and slip that is very comparable to the synthetic control.

Figure 2 shows the results of testing in a water-based can coating. All bio-based alternatives performed well in slip and scratch testing, offering an extremely competitive alternative to the synthetic control.

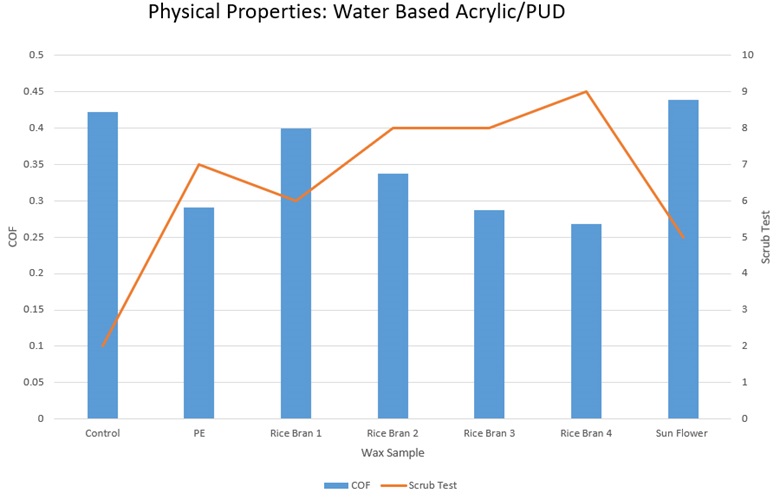

Industrial Coating Results

Figure 3 shows the results from testing coefficient of friction and scrub/abrasion in an industrial coating (water-based acrylic/PUD). The results vary, but rice brans 1 and 2 and sunflower seeds are competitive with polyethylene. All materials performed well in gloss testing in the same industrial coating (chart not shown).

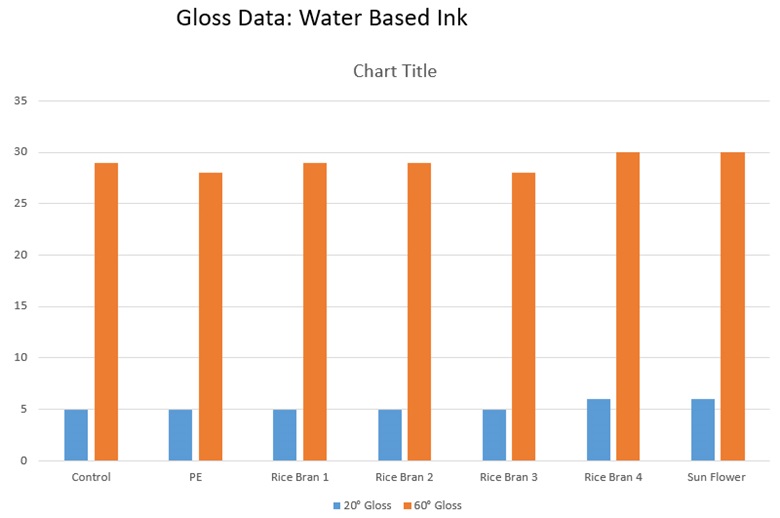

Water-Based Ink Results

In a water-based ink, appearance/gloss data is strong (Figure 4). In scratch tests and abrasion tests, wax brans 2, 3 and 4 are competitive with current standard technology (chart not shown).

Because performance varies for each property by sunflower wax and different types of rice bran wax, there are bio-based alternatives that can work for specific situations. The key is to work with a provider to analyze multiple options to determine the best for each individual formulation.

With these encouraging test results, and as we continue to work with customers to test bio-based wax options, the good news is there are tools already available (or that will be soon) to help formulators who want to use bio-based alternatives. One bio-based wax won’t fit every need, but there are bio-based options for specific applications that can decrease the consumption of fossil resources and help improve the carbon footprint of coatings and inks without sacrificing performance.

Contact us to learn more about the availability of our bio-based waxes and how they perform against conventional wax systems.